Are you thinking about getting an air compressor kit for your air bags and feeling a little overwhelmed by all the options? Don’t worry, you’re not alone. Let’s take a look at the differences and answer some of the important questions you will need to ask yourself when selecting an air compressor kit for your air bags.

Which Brand of Air Compressor Kit?

Which Brand of Air Compressor Kit?

Air Compressor kits are Universal. Air spring and air bag load support kits use 1/4 inch airline tubing, so the air compressors will work with other brands of air bag kits. Do you have Firestone air bags but like the features of an Air Lift compressor kit? Did you buy a truck that has Air Lift air bags or Hellwig air springs on it, but want to install a Firestone air compressor kit? No worries, one brand will work another brand of air springs. Which brand to choose is a personal preference. We have satisfied customers using Firestone, Air Lift and Viair air compressor kits. You really can't go wrong with which brand you select. Find the one that has the features your require and fits within your budget.

Wireless or Analog?

Wireless or Analog?

Wireless air compressors use the latest technology and allow you to inflate and deflate your air bags from inside or outside of your truck. This can come in handy when you want to level out the rear of your truck by allowing you to stand next to the back of the truck and see the change in ride height when inflating or deflating your air springs. They do cost more, but the extra money you spend on a wireless kit can be made up in the reduced time and cost to install the system. Wireless air compressor kits do not require any lines to be run into the cab of your truck, so the install is much less time consuming than with other systems.

Pros of Wireless Air Compressors systems:

- Easy to install – no wires to run into cab

- Inflate / deflate your airbags from outside your truck

- Memory settings for air pressure

Analog air compressors install inside the cab of your truck and are controlled by a toggle switch or button and display the air pressure on a gauge with a needle. Analog systems have been around for years and typically cost less. They will take longer to install than a wireless system because you have to run lines into the cab for the gauge. If you are installing it yourself and have the extra time, it can be less expensive to run an analog system.

Pros of Analog Air Compressors

- Cost less

- Tried and True – Inflating air bags for decades

- Expandable – Allows the use of air tanks

Single or Dual Path Air Compressor?

Single or Dual Path Air Compressor?

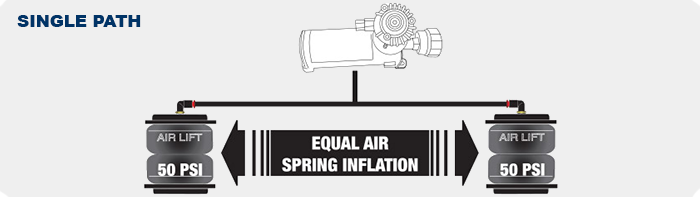

Single path air compressors inflate both air bags at the same time with the same amount of air pressure. This provides equal inflation and is designed for use with evenly distributed loads like travel trailers or 5th wheel trailers. If you tow anything with a trailer hitch, a single path system will work well and provide even air pressure.

Single path common uses (Even loads)

- Travel Trailers

- Boat Trailers

- 5th Wheel and Goosneck Trailers

- Utility and work trailers

- Horse trailers

Dual paths air compressor kits allow you to inflate your air bags with different air pressure amounts. In the diagram above, the air bag with 45 psi would be on the side of your truck with a water tank or heavy tool box. With a dual path system you can do side-to-side or front-to-back leveling. They are commonly used when you have more weight on one side and need to add more air pressure to one air spring to adequately level your truck. If you have a work truck with cargo on one side or a pickup truck with a Lance slide-in truck camper with luggage and supplies on one side, a dual path system is for you.

Dual Path Common Uses (Uneven loads)

- Work trucks

- Flatbed trucks

- Motorhomes

- Slide-in Campers

Standard Duty or Heavy Duty Air Compressor?

Standard Duty or Heavy Duty Air Compressor?

How often you tow is the main factor in determining if you need a standard or heavy duty air compressor. If you are a holiday traveler and only tow your camper once a month during the summer, you will be fine selecting a standard duty air compressor kit. If you have a work truck that is inflating the air bags daily or want more durability and flexibility with your system, we recommend a heavy duty setup with a higher duty cycle that will allow you to run the system more frequently. A heavy duty air compressor will inflate your air springs quicker and often to a higher psi than a standard duty one. If you use your air compressor to pay the bills, have a motorhome that requires higher psi, or are frequently using your air system, we recommend investing a little more upfront for a heavy duty system.

We hope this helps you determine which air compressor system will work best for your needs. If you have any questions, feel free to contact us at 1-800-358-4751. We have been selling and installing air bags and air compressors in our shop for years.